Whatsapp: +86 181 7515 5326

Pressure transmitter: Deep analysis of common used thread types – G, M, NPT, UNF

Pressure transmitters e.g. industrial piezoresistive silicon pressure sensor 4-20ma, high accuracy sputtered thin film pressure sensor for industrial use , or ceramic pressure sensor for oil and air, play a vital role in pressure measurement and control systems. Let’s see the four common thread types on pressure transmitters – G, M, NPT, UNF.

G Thread: The Preferred Choice for Non-sealed Cylindrical Pipe Threads

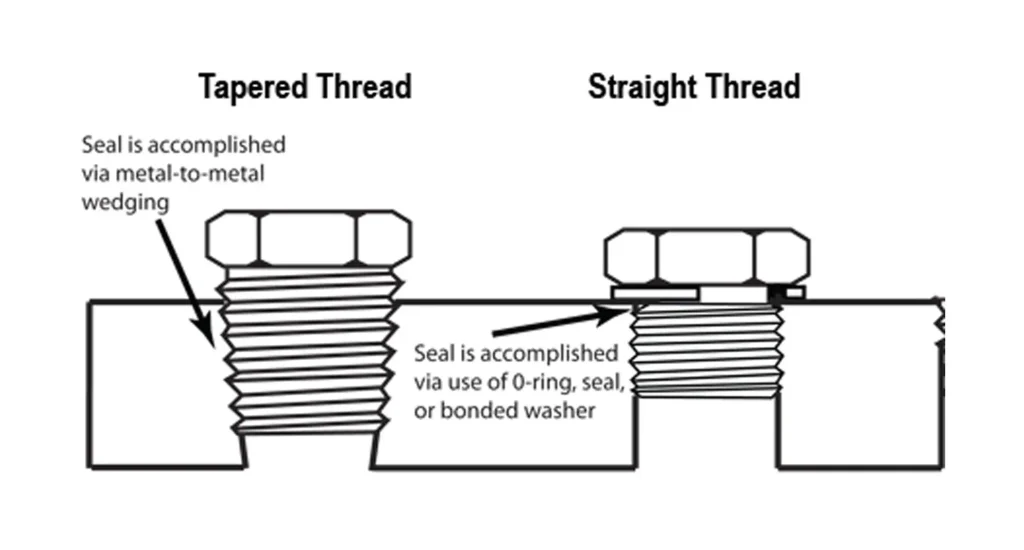

The G thread, representing the 55-degree non-threaded seal pipe thread, is widely used in international pipe connections. Its marking is straightforward, with G1/2″ denoting a cylindrical internal pipe thread with a diameter of 1/2 inch. The G thread is favored by many pressure transmitter manufacturers due to its stable connection performance and good adaptability.

M Thread: The Standardized Choice for Metric Threads

The M thread, or metric ordinary thread, expresses its size and pitch in metric units. For example, M20×1.5 represents a thread with a diameter of 20 mm and a pitch of 1.5 mm. M thread is also favored in the pressure transmitter industry for its precise size control and wide range of applications.

NPT Thread: The Standard in North America

The NPT thread, full name National Pipe Thread, adopts a 60-degree cone design and has excellent sealing performance. It is widely used in pipe and pipe fitting connections in North America, such as NPT 1/2″, NPT 1/4″ and NPT 1/8″. The self-sealing characteristics of NPT thread enable it to maintain a stable connection under high pressure and high temperature environment.

UNF Thread: The Ideal Choice for Precision Applications

The UNF thread, or unified fine thread, is part of the U.S. national precision thread standard. With its fine pitch and excellent sealing performance, it excels in applications that require high precision and stable sealing. UNF thread is commonly used in high-pressure and precision fields such as aerospace and defense, and is also suitable for pressure transmitters that require extremely high connection accuracy.

| Thread Type | Designation | Characteristics | Common Specifications | Pitch |

| Non-sealed Cylindrical Pipe Thread | G | 55-degree angle, non-sealed design, widely used in international pipe connections | G1/2″ | Approx. 1.814mm (14 threads per inch) |

| G1/4″ | Approx. 1.337mm (19 threads per inch) | |||

| Metric Ordinary Thread | M | Metric units, precise dimensional control, widely used in industrial fields | M20×1.5 | 1.5mm |

| American Standard Pipe Thread | NPT | 60-degree tapered pipe design, self-sealing feature, suitable for high-pressure, high-temperature environments | NPT 1/2″ | Approx. 1.814mm (14 threads per inch) |

| NPT 1/4″ | Approx. 1.411mm (18 threads per inch) | |||

| NPT 1/8″ | Approx. 0.941mm (27 threads per inch) | |||

| Unified Fine Thread | UNF | Fine pitch, excellent sealing performance, suitable for precision applications | Based on specifications | Based on specifications |

Note: The above pitch data are common values. In actual applications, they may vary slightly due to differences in manufacturers, standards or materials.

Choosing the correct thread type is crucial to ensure accurate installation and efficient operation of the equipment. If you have any questions or need further information, please feel free to contact us.

Keywords:

Sales contact

Pokcenser Automation Technology Co., Ltd

Mobile: +86 181 7515 5326

Email: info@pokcenser.com

Tel: +86-731-8229 9492