Whatsapp: +86 181 7515 5326

How to Choose the Best Level Sensor for Your Application?

Choosing the right level sensor for your specific application can be a critical decision that impacts both performance and cost-effectiveness. To ensure you select the most suitable sensor, several key factors must be carefully considered. Here are the main points to keep in mind:

1. Media’s Physical Properties

The first consideration is the physical nature of the media you need to measure. This includes:

- Liquid, Slurry, or Solid: The type of media will significantly influence the type of sensor you choose. For instance, liquid level sensors may use float switches, ultrasonic or capacitance principles, while slurry and solid level sensors might rely on vibrating forks, radar or weight-based technologies.

- Corrosive Properties: If the media is corrosive, you will need a sensor made of corrosion-resistant materials such as stainless steel, titanium, ceramic, PTFE… to ensure longevity and reliability.

2. Measuring Range

The measuring range of the sensor refers to the height or depth of the media that needs to be monitored. Key considerations include:

- Minimum and Maximum Levels: Ensure the sensor can accurately measure within the required range, from the lowest to the highest level.

- Continuous or Point Level Measurement: Depending on your needs, you may require a sensor that provides continuous level data or one that simply triggers an alarm at a specific point.

3. Working Temperature and Pressure

The operating environment of the sensor is crucial:

- Temperature Range: Choose a sensor that can withstand the temperature of the media and the ambient environment. High temperatures may require special materials or insulation.

- Pressure Rating: If the sensor will be exposed to high pressures, ensure it is rated to handle those conditions without failure.

4. Environment Condition

The installation environment also plays a significant role in sensor selection:

- Open Area, Still Storage Tank, or Fuel Truck Tank: Each environment presents unique challenges. For example, sensors in open areas may need to be weatherproof, while those in fuel tanks must be explosion-proof and compatible with fuel vapors.

- Accessibility: Consider whether the sensor will be easily accessible for maintenance and calibration.

5. Other Considerations

Several additional factors can influence your decision:

- Accuracy: Determine the level of accuracy required for your application. Some sensors offer high precision, while others may be sufficient for general monitoring. For example fuel level sensor with 0.1% accuracy, and 4-20mA level sensor with 0.5% accuracy.

- Signal Output: Choose a sensor with the appropriate signal output (e.g., analog, digital, wireless) that integrates seamlessly with your existing systems. Some is requesting water level sensor with HART protocol.

- Display: Decide whether you need a sensor with an integrated display for immediate level indication or if remote monitoring is sufficient.

- Budget: Establish a budget and look for sensors that offer the best value for money, balancing cost with performance and reliability.

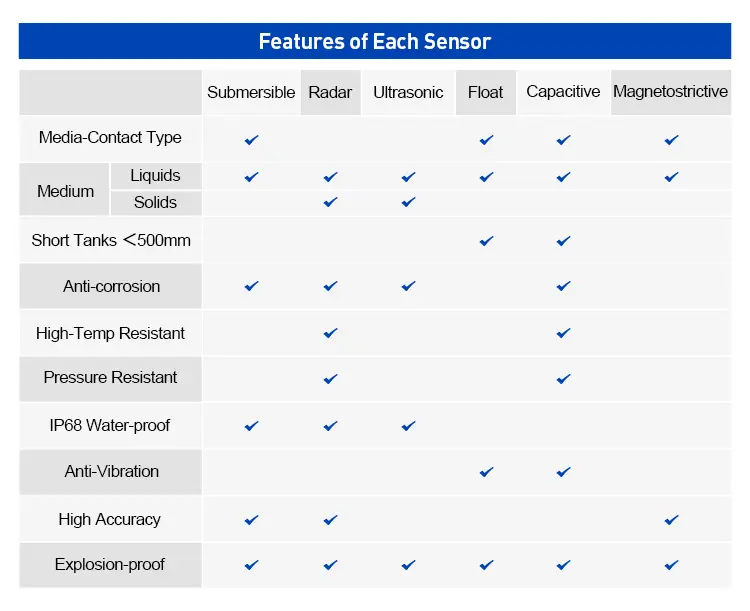

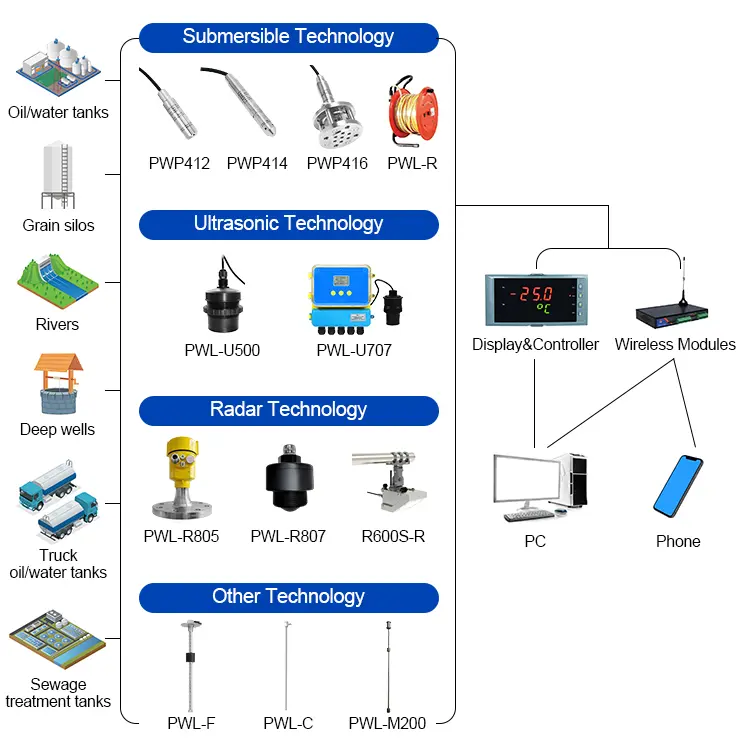

You can choose the best level meter according to the table below:

In conclusion, selecting the best level sensor involves a thorough assessment of the media’s physical properties, measuring range, working conditions, environment, and additional requirements such as accuracy, signal output, display, and budget. By carefully considering these factors, you can ensure that your chosen sensor meets your application’s needs effectively and efficiently.

Keywords:

Sales contact

Pokcenser Automation Technology Co., Ltd

Mobile: +86 181 7515 5326

Email: info@pokcenser.com

Tel: +86-731-8229 9492